An Application That Can Check the Authenticity of Your Plywood

Plywood is a very traditional building material, used on everything from coffins to construction. It’s an ingenious invention, where thin sheets of wood are compressed together to form a single substance. It’s easy to identify plywood; it has a face with the grain orientation running perpendicular to the adjacent faces.

There are two ways to check plywood quality. One is by looking at the manufacturer’s data and examining their certification marks or stamps. The other is to visually inspect the plywood.

How to check plywood quality

Plywood manufacturers use different methods for verifying the quality of their products. These include requirements for grading, chemical analysis, and inspection procedures. The method of grading is based on the quality of the face veneer; this grade will be placed on the plywood at the time of manufacture and should be visible through a viewing window in each sheet of plywood.

The chemical analysis is a method of comparing the moisture content between each sheet to ensure that no moisture is present once the plywood is cut. This would cause weakness and crack to the stress involved in this process. The inspection practices involve visual looks for cracks, checking for face grain orientation, and determining the soundness of the wood.

The field effects of plywood manufacturing include warping, inter-ply wood failure, and splitting at interface joints. Warping is a condition caused by the expansion of the plywood as a result of changes in humidity. This causes cracking in one or both surfaces of the plywood, often referred to as weathering.

In addition to warping, a plywood manufacturer can be held responsible for ensuring that the grain of the wood remains perpendicular to adjacent sections. The presence of deep, shallow, or vertical grain will weaken and can cause splitting at interface joints.

Things to keep in mind while buying plywood

Buying plywood is one of the most important home improvement decisions a homeowner can make. The right plywood will help you to avoid costly mistakes and help you turn your dream home into a reality. Choosing the wrong type, thickness, or colour will result in an inferior project that may not be worth all the effort.

With that being said, there are certain things to keep in mind while shopping for plywood so that you can find what you’re looking for without wasting your time or money on subpar materials.

1. Types of plywoods –

The three main types of plywoods you can buy include marine, construction, and moulding/finish. Each of these options is designed for a specific project or use and will be able to deliver the results you are hoping for with ease.

2. Thickness –

The thickness of your plywood is important because it determines the amount of weight that can be supported. Thicker plywoods are capable of supporting more weight, so they are better suited for use in interior projects where heavier items may be placed on them. Lighter, thinner plywoods are best used in exterior construction due to their lighter weight and ability to withstand strong winds.

3. Sizes –

There are many different sizes of plywood available, including 3/4″, 1″, 2″, and 4″. The thickness of the plywood determines the size and purchase price, so be sure to choose the size that will work best with your project

What is CenturyPromise?

Plywood is a popular building material used for everything from furniture to construction. Unfortunately, it’s also one of the materials most often counterfeited and sold in developing countries. Counterfeit plywood poses a significant risk to consumers, as it could contain harmful substances such as lead or formaldehyde, which may be fatal in high doses.

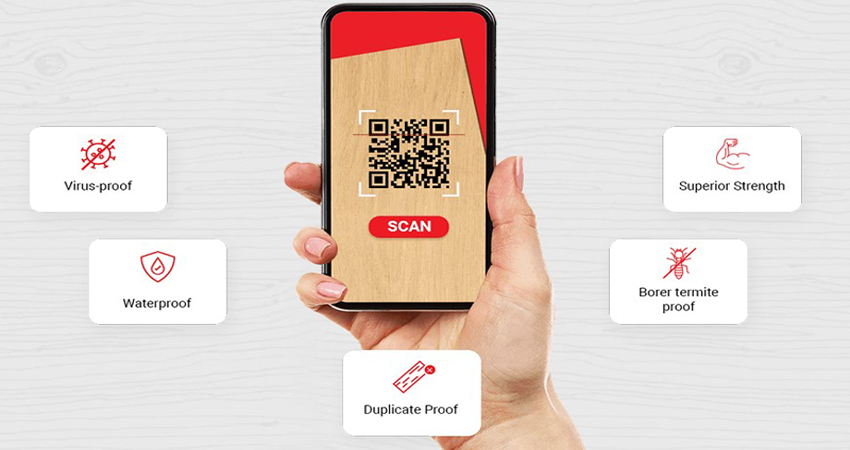

To reduce the risks of fake plywood, use the app CenturyPromise and scan the QR imprinted on your CenturyPly product using the in app scanner and authenticate original plywood.

Conclusion:

Plywood is an engineered wood product manufactured by combining two or more layers of thin sheets of wood, called plies. The product is made with two or more faces of veneer to create one outer layer. Plywood is manufactured in several grades and thicknesses for specific uses. Plywood may be used as a Swordsman resource, building material, and ornamental surface.

Plywood is used within the construction industry for various purposes like furniture and panelling walls; it can also be an important architectural feature of the home. Buy only authentic plywood with CenturyPromise

Ishita Garg