In Depth Information About Super Duplex Plate

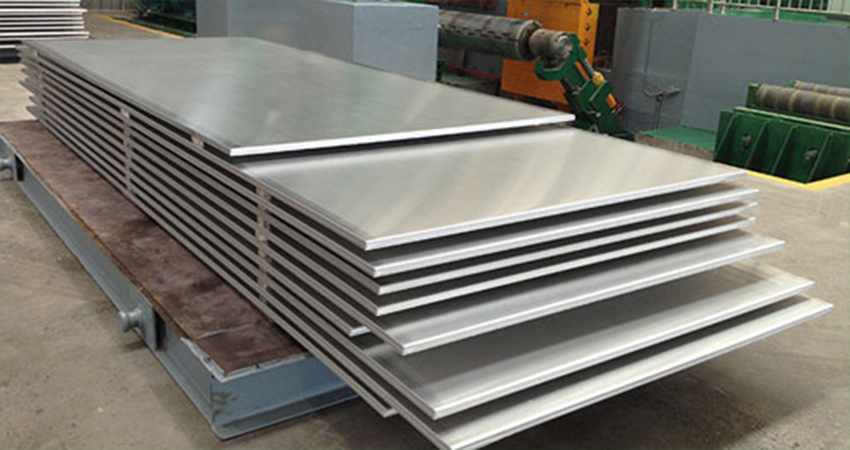

About Super Duplex Plate

Duplex stainless steel plate has low to moderate concentrations of nickel (between 1.5% and 8%) and moderately high levels of chromium (between 18% and 28%). Due to its chemical make-up and balanced (duplex) microstructure, which contains roughly equal volume percentages of ferrite and austenite, duplex stainless steels exhibit good corrosion resistance and outstanding mechanical qualities.

This super duplex material is mostly used in boilers, pressure vessels, offshore platforms, gas and oil industries, heat exchangers, and other chemical processing equipment. In comparison to duplex ones, the plate is made with more materials, making it stronger and even able to withstand higher temperatures. Additionally, it offers resistance to pitting and crevice rust.

The ideal option for many demanding applications is super duplex plate since it has stronger corrosion resistance and strength than duplex plate. Since it is employed in numerous industrial sectors, including the energy, mining, maritime, petrochemical, paper and pulp, and many others.

General Properties

Super Duplex UNS S32760 Plate is a duplex stainless steel plate with nitrogen alloyed 22% Chromium, 3% Molybdenum, and 5-6% Nickel that exhibits outstanding general, localised, and stress corrosion resistance qualities in addition to high strength and exceptional impact toughness.

In practically all corrosive conditions, Super Duplex Plate Supplier has pitting and crevice corrosion resistance that is superior to that of 316L or 317L austenitic stainless steels. Additionally, it possesses higher thermal conductivity and lower thermal expansion than austenitic, as well as high corrosion and erosion fatigue properties.

Compared to austenitic stainless steels, the yield strength is roughly twice as high. This makes the alloy more cost-competitive when compared to 316L or 317L and enables a designer to reduce weight.

Duplex stainless steel plate is best suited for applications requiring a temperature range of -50°F to +600°F. Temperatures outside of this range might be taken into consideration, but they need to be limited, especially for welded constructions.

Features of Super Duplex Plates

- Super Duplex stainless steel is the best and most dependable material choice for applications that require extraordinary mechanical strength.

- Due to its high yield strength, Super Duplex Stainless Steel is able to withstand enormous pressure and load.

- Super Duplex Stainless Steel has every outstanding quality that a person might want in a metal alloy. It is incredibly ductile, robust, long-lasting, and corrosion-resistant. What more is there to ask for?

- The composition and characteristics of Super Duplex Stainless Steel are split 50/50 between ferritic and austenitic.

- When it comes to continuous exposure and lengthy service life, Super Duplex Stainless Steel—which is better than SS 316—is regarded as marine grade steel.

- Crevice corrosion, pitting corrosion, chloride corrosion, stress corrosion, and saltwater corrosion are all easily resisted by Super Duplex Stainless Steel.

- Super Duplex Stainless Steel offers first-rate performance even at temperatures below zero.

- Low thermal expansion and excellent weldability are two characteristics of super duplex stainless steel plates.

Mahesh Patik